☑ Security System PCB Board & PCB Assembly

☑ PCB Fabrication for Smart Burglar Alarm

☑ PCBA in security systems and devices

☑ Full one-stop Turnkey PCB Assembly Services

☑ Intelligent PCBA Manufacturing Factory

With the continuous development of more and more attention to the security intelligent system, the security intelligent system is gradually widely used in various fields, using the combination of advanced and higher security technical methods and traditional security technology, combined with modern communication technology advanced intelligent and information-based security systems are bound to be the development direction of security systems, which promotes the expansion of the security system market.

Security electronic products mainly include peripheral controllers such as smart video monitors, smart burglar alarms, smart access controls, smart parking lot management systems, etc.

PCB assembly manufacturing in the security electronic achieves functions such as indoor anti-theft, anti-robbery, fire prevention and gas leakage prevention, and emergency rescue, etc., and easily realizes intelligent home security, without worrying about the safety of home, property, and life.

In the era of intelligence, the application rate of security PCB assembly is also extremely high, and the security PCBA is used for prevention needs in life, which brings convenience to our daily lives.

Intelligent security systems from analog surveillance to digital surveillance and now network video surveillance, cameras gradually to high-end intelligence, high-definition pixels closer, which will be the image transmission speed, clarity, video storage length, and data analysis have put forward higher requirements.

While improving the security system solution, the heat flux density and calorific value of printed circuit board systems are also increasing day by day. As we all know, the operating temperature of electronic devices directly determines their service life and stability, and heat dissipation has become a measure of product performance in the PCB electronics industry important indicators, especially the heat dissipation of surveillance cameras.

In practical applications, if the core PCB assembly temperature is too high due to poor heat dissipation, it is easy to cause a series of thermal faults such as a blurred monitoring screen, packet loss, code error, and restart, which will bring great inconvenience to users. Therefore, special attention should be paid to whether the PCB material has the characteristics of low oil separation and low volatility when selecting materials.

SCSPCBA, as a comprehensive PCBA factory, for the security field, which is an ever-growing and high-standard industry, we are constantly improving our management style, introducing high-precision equipment, and actively seeking and cultivating talents in this field, just to better provide high-quality services and safe and reliable products.

We believe it is the ability to consistently provide one-stop full PCB assembly service and value that exceeds customer expectations. We gain customer recognition by:

• Continuous attention to customer needs

• Key quality management system

• Data-driven management

• Specialised resources and centralized training

• Certification to industry standards

• Commitment to customer satisfaction

At present, we have mastered and accumulated relevant technologies and experiences in this field of PCBA assembly. The PCBA has been successfully used in a series of products such as surveillance cameras, fire alarms, fingerprint door locks, smart video monitors (intelligent video surveillance), smart burglar alarms, smart access control, smart parking lots, and smoke detectors. At the same time, it has been recognized and trusted by many customers and established a strategic partnership.

SCSPCBA knows that safety and security products require the highest level of reliability requirements in every environment. We support our customers' needs through high-quality electronic manufacturing services, new product introduction (NPI), product traceability and raw material control, and better sourcing channels.

Our professional PCB assembly engineers and project teams have extensive experience in assisting our customers in bringing new security system products to market. We provide one-on-one technical support to our customers, making seamless communication on security electronics PCB assembly projects.

The reasons that customers in the Security Industry choose us as their PCBA manufacturer:

The security sector has high requirements and expectations for product quality and all aspects of production, especially in PCB assembly, which determines the core functionality and main value of most products in the security sector.

High-quality circuit board assemblies (PCBAs) provide a critical foundation for electronic products, intelligent systems and security interfaces. As the demand for smarter buildings, security and access control systems continues to grow in the residential, commercial and industrial markets, it is becoming increasingly important to have high-quality PCB control circuits to coincide with advanced systems, software, and functionality.

Some of the Applications In The Security Field:

● CCTV Surveillance Cameras

● Fingerprint Combination Locks

● RF Card Reader

● Access Control System

● Face Recognition System

● Fire Alarm System

● Smart Video Monitor (Intelligent Video Surveillance)

● Smart Burglar Alarm

● Smart Access Control

● Smart Parking Lot

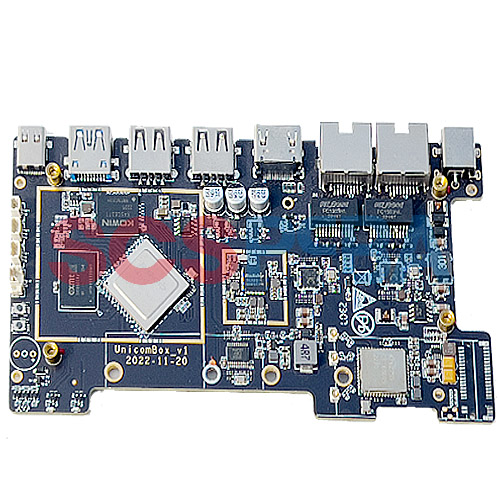

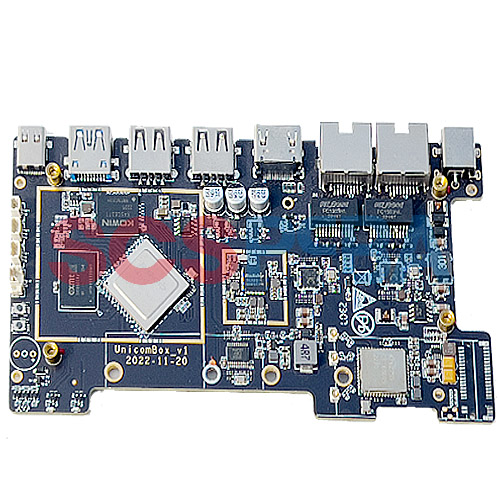

● Module Boards on PCBA Backplanes for Security Sensing

The thickness of the stencil is controlled between 0.12-0.15 mm. If the thickness of the stencil on the module pads cannot reach 0.12 mm or more due to 0201 or other fine-pitch components, it is necessary to use a stepped stencil to partially thicken the stencil to ensure that there is enough in on the module soldering.

Security sensing PCBA board on the module board stencil openings needs to be individually optimized, and the pad width direction of the upper and lower sides needs to be cut to prevent tin bead processing. The pad length direction needs to be cut inward and outward to increase the amount of tin.