HOME /Products /PCBA Services /PCBA Repair

☑ SCSPCBA Profession Repair Teams

☑ Call Us Now!

☑ Request Your Free Quote Today

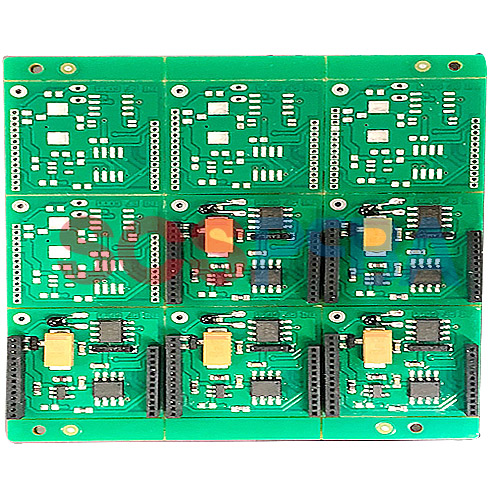

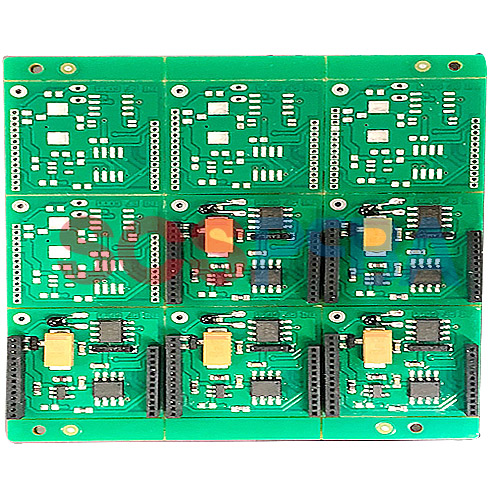

SCSPCBA has complete equipment and a professional technical team, that can provide PCBA (Printed Circuit Board Assembly) maintenance services, a complete maintenance process, and professional maintenance personnel, capable of repairing various PCBA failures.

SCSPCBA Frequently Used Tools and Materials in PCBA Repair

Welding Tool

Includes soldering iron, solder wire, solder paste, and more for joining and repairing components and connectors on PCBs.

Test Tools

Including multimeters, oscilloscopes, etc., used to check the connectivity, voltage, current and other parameters of components on the circuit board.

Toolbox

Includes common tools such as pliers, wrenches, tweezers, and more for adjusting and removing components and connectors on PCBs.

Electronic Component

If you need to replace components on the PCB, you need to prepare corresponding components, such as capacitors, resistors, transistors, etc.

Maintenance Manuals and Literature

Including PCB wiring diagrams, circuit diagrams, component specification sheets, etc., used to determine the location and connection method of components on the PCB, and to check the parameters of components.

Cleaning Supplies

Including cleaning cotton, alcohol, etc., used to clean solder slag, dirt, etc. on the PCB.

In The Process of PCB Assembly Failure Maintenance, We Analyze The Cause of PCB Failure According to The Following Aspects:

Visual Inspection

Check the appearance of the circuit board for obvious damage such as burnt, oxidized, and cracks, and check whether the components such as connectors, capacitors, resistors, triodes, diodes, and integrated circuits are normal

Component Testing

Use multimeters, oscilloscopes, signal generators and other testing instruments to test whether the components work normally, such as capacitors, resistors, transistors and other components may fail due to aging, expiration of service life or electromagnetic interference, resulting in the circuit not working properly

Signal Detection

Use an oscilloscope to check whether the signal link is normal. The connectors or solder joints in the PCBA may be loose, broken or poorly welded, such as checking the clock signal, data signal, control signal, etc., resulting in circuit disconnection or abnormal signal transmission

Thermal Imager Inspection

Use a thermal imager to check the temperature distribution on the circuit board. Because the components in the PCBA need to dissipate heat, find out the hot spots and overheated areas. If the heat dissipation is not good or the circuit design is unreasonable, it may cause the components to overheat and burn. These places may be the point of failure on the circuit board

Hardware Debugging

The fault point is determined by hardware debugging of the circuit board, such as connecting an external signal at a specific point and observing the reaction of the circuit to determine the fault point

Software Debugging

Check whether the program is correct during software debugging, such as whether the program is loaded correctly, whether the peripherals are correctly identified, whether the data processing is correct, etc

Fault Simulation

Fault simulation of the circuit board, simulating the working state of the circuit board under different conditions to find out possible fault points

Procedural Issue

If there is a chip in the PCBA that needs to be programmed, there may be a program error or a problem with the chip itself, resulting in the circuit not working properly

Once The Problem Spot is Found, We Will Repair It. The Maintenance Process Includes The Following Steps:

Diagnose the Problem

Identify PCB failures and identify the root cause of the failure to determine what needs to be done.

Disassembly and Cleaning

Remove the PCBA from the equipment and clean it for better inspection and maintenance

Replacement Parts

Identify the part to be replaced and remove it with the proper tools and techniques. For example, if it is found that a certain component needs to be replaced, it is necessary to prepare replacement parts for the component, as well as corresponding welding tools, etc.

Welding

Use a suitable soldering tool to mount the new component to the board.

Reprogram

If reprogramming is required, download the program to the PCBA

Test

Test the repaired PCBA to make sure it works properly

Clean and Organize Again

Clean up solder slag and dirt on PCB, and organize lines, components, and connectors, etc.

Acceptance and Delivery

Final acceptance to ensure the PCB is back in working order and the repaired PCB is delivered to the customer

It should be noted that special care is required when performing PCB repairs to avoid secondary damage to the PCB and components. If you are not sure about the operation steps, you can consult the professional maintenance engineers or engineers of SCSPCBA.