☑ Fueling New Energy Electronics through Expert PCBA

☑ Crafting the Future with Our PCBA Manufacturing

☑ Leading the Charge in PCBA for New Energy Tech

☑ Your Partner for New Energy Electronics PCBA

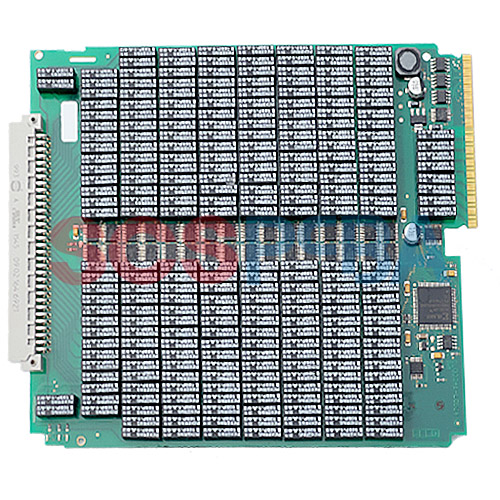

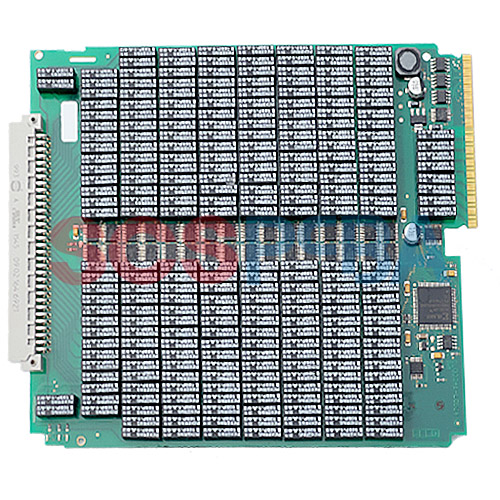

Printed circuit board assembly (PCBA) is the core part of new energy products, which requires professional PCB factories and SMT factories to complete. By producing PCB assembly manufacturing, purchasing components and then assembling them into complete new energy products, testing, quality inspection, packaging and sending to customers, and providing repair and rework services.

Especially in recent years, new energy products, as a sunrise industry in the new era, have become the favorites of professionals. Therefore, the demand for PCB assembly of new energy products is also very large, but if PCBA does not have high-level technology and industry experience to support it, will inevitably bring many problems to new energy products. In terms of new energy products, especially the active parts of new energy vehicles, if something goes wrong, the car will be destroyed.

The new energy electronic product market brings several major categories together such as photovoltaic modules, energy storage systems, new energy lighting (LED), and new energy vehicles.

Therefore, every new energy product PCBA requires absolute precision control and quality control, which is why you need to find a professional, high-level PCB assembly manufacturer with many years of experience to cooperate with, and in the process, you can see very clearly all the details, including PCB Design, components, PCB manufacturing, PCB layout and quality control of each step of PCB assembly.

1. Equipment accuracy

2. Standardization of operators

3. Product quality control

4. Strict implementation of acceptance standards

When producing new energy-printed circuit boards, the quality of the products must be guaranteed, and the acceptance standards of the PCB assembly industry must be strictly followed. Especially for new energy vehicles, most of them will have an IPC3-level acceptance standard and PPAP document requirements. We must follow the product province One of the requirements is strictly implemented, whether it is in terms of appearance, functionality, or packaging protection, it is particularly important, because the quality of PCB products is related to the quality of subsequent PCBA products and the performance of the final product.

Certification quality is very important in the new energy industry. Especially for new energy vehicles, which are used for safe driving a factory with vehicle quality certificates and IPC3-level acceptance standards is very important. Perfect certification helps to provide high-quality products.

A complete supplier system has a professional and excellent supplier channel, continuous and stable cooperative relations, guaranteed quality of component procurement, easy cost control, unified integration of components and other material component resources, reducing repeated purchases and reducing losses, Reducing costs is also the key to choosing a supplier.

Qualified equipment types can provide more accurate experience and reports for products while saving time and money, and contributing to quality improvement. Effective circuit design and high-efficiency new energy product PCBs are essential to ensure that products function as expected.

· SCSPCBA has rich experience in PCBA manufacturing, especially in the field of new energy electronics, including New Energy Vehicles, Electric Vehicles, Electric Vehicle Charging Stations, Energy Storage, Solar Panels, Photovoltaic Panels, etc

· SCS has complete PCB and PCBA certification to ensure customer quality and product certification requirements.

· PCB certification : ISO 9001:2008, ISO 14001:2016, IATF16949, SGS-RoHS, SGS-REACH, OHSAS18001: ISO 13485

· PCBA certification: ISO 9001:2008, ISO 14001:2016, TS16949

· Our new energy PCB assembly manufacturing follows strict quality control processes and standards, including printed circuit board inspection and testing links during the manufacturing process.

· Make sure that the PCBA is a qualified quality product in new energy products, and avoid failures and losses caused by low quality.

· We manufacture PCBA for various new energy products, including photovoltaic cells, automobiles, charging piles, lithium batteries, wind turbines, and various new energy sources Product production experience. Has 15+ years of product production experience and overseas export experience. There are many years of stable cooperation with domestic and overseas customers.

· We have advanced PCBA manufacturing technology and equipment, which can meet the special requirements of new energy electronic products.

· We can handle high-density circuit board layouts and tiny components to meet the design requirements of new energy products.

· Our PCB and PCBA factories are fully automatic intelligent equipment, and have independent new energy product production lines, with independent new energy product delivery acceptance standards, from precise assembly of smaller components to creating complete kits for customer assembly.

· Our PCB and PCBA factories have a complete departmental system.

· Each department makes full use of the resources of the division of labor and refinement to reduce unnecessary expenditures. It is more efficient, more guaranteed in quality, and easier to control.

· Professional one-stop PCBA custom processing, for new energy products in responding to emergencies that may arise during the production process.

· We deliver PCBA on time to avoid delays in the project schedule due to late delivery.

· We provide a PCBA technical team with good customer support and communication so that we can solve problems about new energy PCB assembly manufacturing and other new energy PCB design needs promptly when needed.

Safe, reliable, and intelligent new energy industry application solutions. The global energy industry has experienced a profound revolution from high-carbon to low-carbon, from low-efficiency to high-efficiency, and from partial balance to large-scale configuration. In 2030, the world is expected to present safer, greener, smarter, And more interconnected new energy application scenarios.

The solar panel connection system is responsible for the complete transmission of the electric energy converted by the solar panel, which is efficiently and stably transmitted to the confluence town and the important part of the inverter, which seeks high reliability. It has a long service life and is resistant to harsh environments.

With the development of photovoltaic power generation technology, PCBA technology pursues the new requirements of reducing environmental pollution, improving the comprehensive utilization rate of energy, and improving the reliability of power supply.

Wind energy inverters play a very important role in wind power generation systems. The electric energy generated by wind turbines is rectified and inverted by wind energy inverters and then incorporated into the grid. Canon directly affects wind power quality and reliability and stability of wind power generation systems. In the future, high-power wind turbines require high-oxygen connection technology for wind energy converters to be the first choice.

Modular, stable operation The safe operation of the pitch system is an important guarantee for the efficient and stable operation of the wind power system. With the development of wind turbines in the direction of high efficiency and large capacity, more stringent requirements are put forward for the control accuracy, stability and intelligence of the pitch system, and the innovative intelligent connection technology will become the key to upgrading the pitch system Strong guarantee.

The control and protection system switches the main positive circuit, the main secondary circuit and the pre-charging circuit in new energy vehicles and energy storage systems, and plays a protective role in over-current, over-voltage and battery under-voltage, which will directly affect The safety of electric vehicles requires that the components in the control and protection devices must have high reliability to ensure efficient operation and protect the personal and property safety of consumers.

The new national standard for DC & AC charging piles is resistant to temperature rise and small in size. Due to safety, battery life and obvious cost advantages, the country adopts AC charging as the main method and DC as the auxiliary method for electric vehicle charging piles. construction ideas.

The AC charging pile provides AC control power for the electric vehicle on-board charger, so the requirements for the current, temperature, and voltage of the connecting parts are higher.

The DC charging pile can provide a DC power supply device for the off-board power battery of the electric vehicle. Its charging speed is fast, the input voltage is high, and the output current is large, which has high requirements for heat dissipation, safety, and reliability of components.

BMS plays a role in testing and managing batteries in new energy vehicles and energy storage systems and is an indispensable part of power and energy storage battery packs.

Due to the long-term environment of vibration and corrosive gas, the stability of data transmission and the real-time response of battery status become the primary guarantee of system safety, and the reliable connection in harsh environments becomes a necessary condition for the safe and efficient operation of BMS.