☑ PCB Assembly Medical-grade Medical Electronic Equipment

☑ PCB Design Household-grade Medical Electronic Equipment

☑ Applications of PCBs for the Medical Industry

☑ Trustworthy PCB Assembly Partner

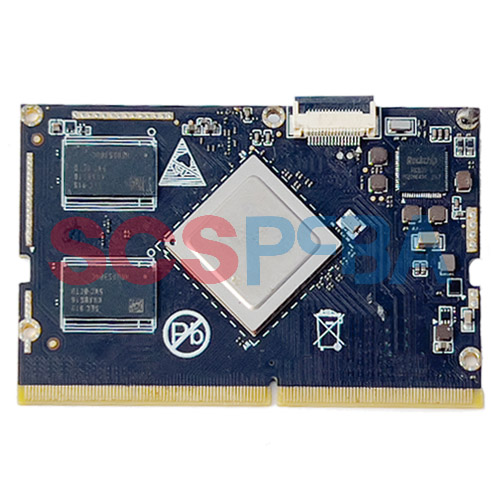

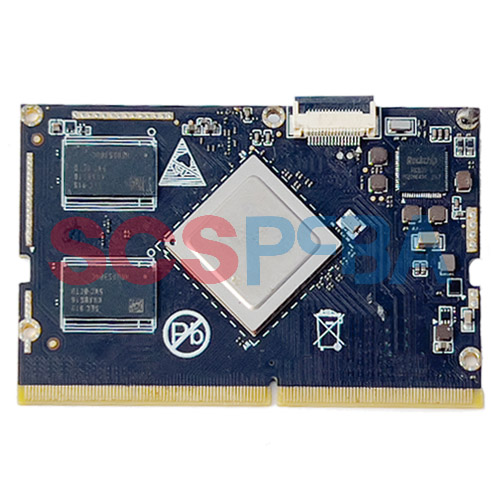

☑ High-Quality and High-precision Multi-layer PCB

Medical electronics is divided into medical-grade medical electronic equipment and household-grade medical electronic equipment.

Printed circuit board assemblies (PCBA) are a core part of medical devices, but not every PCB Assembly Manufacturer has the ability to manufacture them in-house, assemble them into complete medical devices, perform quality control testing, and provide repair or rework services. Working with PCBAs requires a high level of medical electronic technical expertise, as well as the efficiency of handling many small components with great precision.

Regardless of medical-grade medical electronic equipment or household-grade medical electronic equipment, every PCB assembly manufacturing requires absolute precision and quality, which is why it's important to work with a medical device contract manufacturer. You can trust - and see your medical electronic printed circuit board manufacturing plan from start to finish, with no detail missed in the middle.

Medical electronic equipment PCB fabrication must comply with relevant medical industry standards and regulations, such as ISO 13485, etc. These standards ensure that the design, manufacture and use of PCB meet the requirements and safety of medical devices.

Choose PCB materials electronic that meet medical standards, and if necessary, medical-grade materials should be used. Avoid the use of hazardous substances and non-compliant materials to prevent potential hazards to patients and users.

Medical electronic equipment printed circuit boards are usually exposed to harsh environments and are susceptible to contamination by bacteria, viruses, etc. During production, ensure that PCB fabrication are properly cleaned and sanitized prior to assembly to prevent cross-contamination.

Medical electronic PCB design must have high reliability and stability to ensure the stable operation of medical equipment. Avoid single points of failure and system-level failures, and optimize printed circuit layout and signal transmission to reduce the risk of failure.

In the production process of medical electronic PCB, it is necessary to strictly control the production process to ensure the quality and consistency of the PCB board. Sufficient PCB assembly testing and inspection are carried out to exclude manufacturing defects and defective products.

Medical PCBs are usually used as an integral part of medical equipment. It is necessary to ensure the compatibility of PCBs with other systems to ensure the overall function and performance of the equipment.

Medical equipment is used exclusively for life-saving purposes. So, quality control is very important in PCB manufacturing. Choose a PCB manufacturer who strictly adheres to the regulatory requirements for medical PCB manufacturing. Regulatory requirements help to provide medical-grade and household-grade quality medical electronic equipment.

Experience It is important to consider this factor when choosing a medical PCB manufacturer. You can look up the number of years the PCBA company has been established. How much work has it done in the past?

Qualified equipment can provide more accurate experience and reports for products, save time and money, and help improve the quality of medical products. Effective circuit design and efficient medical device PCBs are critical to ensuring that medical devices perform as intended.

The operation of an enterprise and proper guidelines are particularly important for the control of product quality

Whether it is medical-grade medical electronic equipment or household-grade medical electronic equipment, we have relevant quality certifications in PCBA manufacturing, such as ISO 13485 (quality management system certification for medical devices). These certifications show that the manufacturer meets the quality standards of the medical industry and has the ability to provide high-quality products. At the same time, we also provide PCB assembly testing services to help you reduce risks and improve quality.

Medical electronic equipment involves complex technologies and requirements. We have rich experience and expertise in PCB assembly manufacturing for medical electronic equipment and can provide stable and reliable PCB designs, from accurately assembling smaller components to creating complete PCBA packages for customer assembly, We will provide you with one-stop service throughout this process.

We have a strict quality control process and testing methods for PCBA Manufacturers. A good quality control process can ensure the consistency and stability of each medical electronic device PCB assembly.

We are a PCBA manufacturer with sufficient production capacity and capacity to meet your needs in medical electronic equipment PCB and can provide fast delivery when needed.

We make sure that we can provide good technical support and after-sales service for medical electronic equipment PCBA. Because medical equipment often requires long-term maintenance and support, it is critical to ensure the normal operation of the equipment. We provide a variety of PCBA appearance, function and PCB board-level repairs, completed by well-trained and experienced personnel in accordance with IPC standards.

The production of wearable devices is expanding in large proportions. Additionally, wearable medical devices include fitness trackers, blood pressure monitors, and smart health watches.

Medical PCBs can be used in scanning equipment including ultrasound scans, CT scanners and X-ray screens using medical PCBs. Additionally, the computers that analyze the images captured by these scanners require expertise in PCB design and PCB assembly.

Since electronic health record systems are not well integrated, EHRs are taking bold steps to integrate patient details. In addition, the electronic health record (EHR) can help collect data on specific populations, which can help to carefully study the success rate of treatments and drugs. Therefore, finding a professional PCBA manufacturer is of great help to the medical treatment of electronic health record equipment.

PCBA (Printed Circuit Board Assembly, Printed Circuit Board Assembly) wireless communication equipment used by hospitals using instant messaging applications and walkie-talkies can help achieve efficient communication and coordination within the hospital and improve the efficiency of the medical team.

For example:

· Healthcare workers can send and receive text messages in real-time, and chat one-on-one or in groups. This can quickly deliver information such as patient status updates, emergencies, surgery schedules, etc. for a timely response.

· The walkie-talkie feature allows medical staff to make real-time voice calls without making calls or sending text messages. This is especially useful in emergency situations, such as quickly calling a medical team for first aid or emergency surgery.

· Security and privacy protection are of paramount importance for internal hospital communications. These wireless communication PCBA devices should adopt encrypted communication and other security measures to prevent unauthorized access and information leakage.

· Some PCBA wireless communication devices may integrate other functions, such as location tracking, call buttons, etc., to improve the overall management efficiency and patient care quality of the hospital.

Medical PCB (Printed Circuit Board) is one of the core components of implantable medical equipment, especially in implantable medical equipment such as cochlear implants and defibrillators, medical PCB plays an important role.

· Cochlear Implant

A cochlear implant is an implanted medical device used to treat severe hearing impairment. Medical PCBs are responsible for receiving, processing and transmitting sound signals in cochlear implants. It receives external sound signals and converts them into nerve impulses, which are then transmitted to the auditory nerve through an electrode array implanted in the ear, allowing hearing-impaired patients to restore partial hearing.

· Defibrillator

A defibrillator is a medical device used to combat serious arrhythmias such as ventricular fibrillation or ventricular tachycardia. When ventricular fibrillation or ventricular tachycardia occurs, the defibrillator releases electric shock pulses through the medical PCB control electrodes to restore the normal rhythm of the heart.

Medical Device PCBAs play a key role in monitoring devices used in healthcare systems, especially in medical devices such as blood glucose monitors and body temperature monitors.

· Blood Glucose Monitor

A blood glucose monitor is a device used to measure a patient's blood sugar level. The medical equipment PCBA is responsible for controlling and managing the measurement process in the blood glucose monitor, receiving and processing data from the blood glucose sensor, and displaying and transmitting the measurement results. It ensures accurate data collection and reliable monitoring of blood glucose levels, helping diabetic patients with daily management and treatment.

· Temperature Monitor

A temperature monitor is a device used to measure a patient's temperature, which can be a portable electronic thermometer or a continuous monitoring system. The medical equipment PCBA is responsible for processing the body temperature data measured by the sensor in the body temperature monitor, and displaying the results on the screen. At the same time, it can transmit data with the medical system to realize remote monitoring and data recording.