☑ Empowering Your Industrial Control Vision with Expert PCBA Manufacturing

☑ Your Trusted Partner for PCB Design and Manufacturing

☑ Industrial Control Electronic PCB Assembly Fabrication

☑ Your Design, Our Expertise PCBA Design and Manufacturing

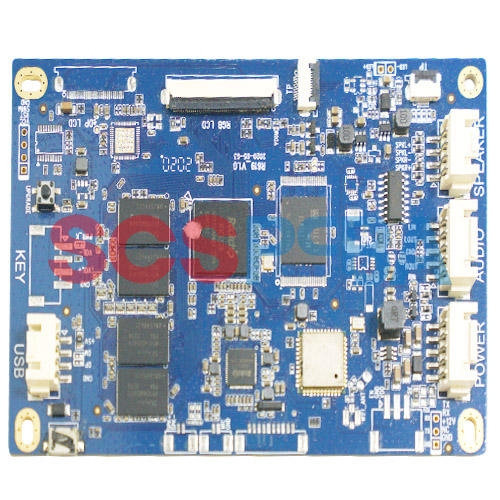

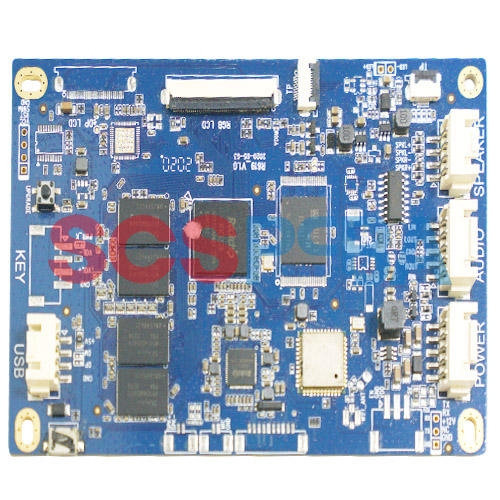

The industrial control PCBA board is a circuit board specially used in the field of industrial control and is an important part of the modern industrial automation control production process.

Industrial control electronics include a programmable logic controller (PLC), touch screen, industrial computer, contactor, thermal relay, motor soft starter, frequency converter, button, indicator light, relay, etc. Industrial control refers to industrial automation control, which is mainly realized by a combination of electronics, machinery, and software.

Due to the complex use environment of industrial equipment, industrial control boards should work normally under high temperatures, high humidity and high corrosion conditions. Industrial control printed circuit board assembly should have the characteristics of high integration, good stability, and strong anti-interference ability, and can meet various industrial automation production environments.

A good industrial control PCB assembly board can effectively reduce the probability of failure of industrial control equipment during the operation.

Industrial control pcb circuit boards have special boards and general boards.

● Dedicated PCB Boards

the PCB boards designed for a specific function, such as a temperature control board. After purchase, the input port is connected to a thermocouple and the output port is connected to a heating contactor or solid-state relay to control the heating device for temperature control and flow.

● General PCB Boards

Most of the general-purpose control panels can be programmed to complete specific functions after secondary development by users themselves and have a wide range of uses. For example, PIC is a generic industrial control board. After the user writes the program and edits the input, various functions can be completed. Digital input, analog input ports, high-speed counter ports, digital output ports, and analog output ports, also have communication functions.

PCB assembly manufacturers formulate unique process flow and testing methods according to the characteristics of industrial control printed circuit boards to ensure that PCB meets the quality requirements of industrial equipment. Nowadays, the application of industrial automation equipment is more and more extensive, and industrial equipment is becoming more and more automated and intelligent, especially with the development of Internet technology, intelligent network equipment is becoming more and more popular. The advantages of PCB circuit boards in the field of industrial control are constantly improving.

Industrial control motherboards generally use low-power CPUs. Because they are suitable for wide-temperature and wide-voltage application environments, the printed circuit board layout and PCB assembly design of the CPU require more precision and detail.

The selection of components for industrial control motherboards needs to be verified, and the selection of materials will be relatively strict. It needs to be resistant to high temperatures and humidity, to ensure that the industrial control motherboard can work normally in harsh environments;

The motherboard has more stable solid capacitors and ceramic capacitors, instead of electrolytic capacitors that are generally used on ordinary motherboards.

The number of PCB layers of industrial control motherboards is generally 6 layers, and ordinary motherboards are generally 4-layer PCB design. Multi-layer PCB board design can strengthen the motherboard's anti-electromagnetic interference, and electromagnetic compatibility, and enhance the stability of the motherboard.

The interface design meets the requirements of the market. The finished industrial computer motherboards on the market have a large number of standard interfaces to meet various needs.

· Choose an industrial control PCB fabrication with many years of rich experience

· With advanced production PCB assembly equipment

· Professional PCBA manufacturing technology

Manufacturer with perfect quality certification, PCBA manufacturer with 100% test before delivery.

Large-scale factories need to continue to operate without stopping, research laboratories need to run programs for several days to do simulation calculations, and self-service terminals such as airport gates need to be released for a long time. All these pose challenges to the stability of industrial computers and industrial control motherboards.

Therefore, when choosing a manufacturer of industrial control PCBA, it is necessary to pay attention to the quality of printed circuit board assembly to ensure that the industrial control motherboards they produce can be used normally for a long time under the factory's temperature, dust, humidity, vibration, impact and other environments.

Choose a PCBA manufacturer with an efficient and complete supply chain system and perfect after-sales service.

In addition to reliable industrial control PCBA, PCB assembly manufacturers can also provide worry-free one-stop services from PCB prototype manufacturing to project delivery according to customer needs, helping customers in various fields to realize business intelligence.

● Rich Experience in PCBA Production

With more than 10 years of experience in PCBA production, it means that our team has accumulated rich knowledge and experience in the field of PCBA industrial control manufacturing.

● Automated Production

Printed circuit board manufacturing, We use more automated equipment and circuit board technologies, such as automated printing and placement, which can improve production efficiency and accuracy, and reduce the risk of human error.

● State-of-the-art Equipment

Invest in the latest printed circuit board manufacturing equipment, such as high-precision cutting machines, drilling machines and surface mount equipment. These devices can provide higher industrial control PCBA quality and precision.

● IPC Standards

Complete production in strict accordance with IPC standards, enabling us to create durable PCB and PCBA that can guarantee product stability

● Quality Control

After years of experience, we PCB assembly team has established a sound quality control system, including inspection, testing, and verification processes. Using high-precision measuring equipment and testing tools to ensure that each printed circuit board meets the specified requirements and standards.

● Material Selection

Select high-quality and reliable materials, such as reliable substrate materials, reliable electronic components, and soldering materials that meet environmental protection requirements. This ensures that the industrial control printed circuit board maintains stability and reliability in long-term use.

● Technical Expertise

During the long-term PCB assembly fabrication production process, our team has mastered various advanced technologies and processes. This includes SMT, DIP, soldering techniques, testing methods, etc. Our team can handle complex and high-density industrial control circuit boards.

● Process Optimization

Through years of practice and feedback, our team has optimized the PCBA manufacturing process many times. We have implemented the best processes and operating methods to improve industrial control PCBA production efficiency, reduce costs, and ensure the quality of printed circuit boards.

● Continuous Improvement

We regularly evaluate and improve the PCB assembly manufacturing production process, look for potential problems and bottlenecks, and take corresponding measures for improvement. Improve production efficiency and product quality through continuous optimization and innovation.

● Quality Certification

Our strict quality assurance system has earned us an excellent reputation and is ISO 9001:2015 and IATF16949 certified

● Problem-Solving Ability

In the long-term PCB assembly fabrication production experience, we have encountered various problems and challenges, such as assembly problems, circuit failures, design defects, etc. By solving these problems, our team has accumulated rich problem-solving abilities and production industrial control PCBA skills.

● Customer Satisfaction

Our team has been operating in the field of PCBA production for 10 years, and we have established a group of loyal customers. They have a sense of trust in our PCBAs and services and are satisfied with our delivery capabilities and the quality level of our industrial control PCBAs.

● Training and Technical Support

We provide the necessary training for our employees to ensure that they are familiar with the latest PCBA manufacturing technology and operating procedures. At the same time, establish a well-trained and experienced technical support service team to provide customers with professional technical consultation and support.

In modern industrial automation production, a high-performance industrial control PCBA board can not only save the tedious and repetitive work of manual operation but also reduce production costs and improve production efficiency. It is one of the necessary pieces of equipment to realize industrial automation production.

● Industrial Computers and Industrial Computers

The common ones are PC bus industrial computers, programmable controllers, distributed control systems, field bus systems and numerical control systems.

● Laser System

Fiber laser marking machines, high Basic industrial equipment such as high-power laser cutting machines, high-power laser welding machines, servo motors, milling machines, and shield machines are used in large-scale mechanized production.

● Industrial Instruments and Meters

The instruments and meters of mechanical industrial products include industrial automation instruments, electrical instruments and meters, optical instruments, analytical instruments, laboratory instruments and devices, material testing machines, meteorological instruments, film machinery, etc.

● Smart Meters

The smart terminal of the smart grid, in addition to the basic power consumption measurement function of the traditional electric energy meter, also has two-way multiple rate measurement functions, user terminal control functions, and multiple data transmission modes in order to adapt to the use of smart grids and new energy With intelligent functions such as two-way data communication function and anti-theft function. Smart meters represent the development direction of intelligent terminals for end users of energy-saving smart grids in the future.

● Motion Controller

Motion controllers are mainly divided into three categories, namely PC-Based, dedicated controller, and PLC. Among them, PC-Based motion controllers are widely used in industries such as electronics, equipment, and machine tools; representative industries of dedicated controllers are wind power, photovoltaics, robots, molding machinery, etc.; PLC is popular in industries such as rubber, automobiles, and metallurgy.