☑ Instantly Quote & Order Today

☑ 5G Connectivity Starts with Precision PCBA Manufacturing

☑ Transform Your Network with Our 5G-Optimized PCBA

As the foundation of information and communication, 5G is crucial to economic transformation and social life. As a basic industry of the national economy, the transportation industry is an important link for the development of the economy and other social undertakings, and it is also the primary condition for ensuring the development of the regional economy. Based on the indoor positioning capabilities provided by new positioning technologies such as 5G and Bluetooth, as well as outdoor navigation capabilities such as GPS and Beidou, smart travel methods can be quickly planned.

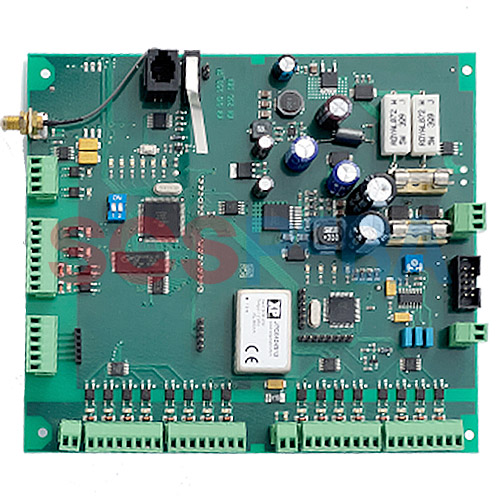

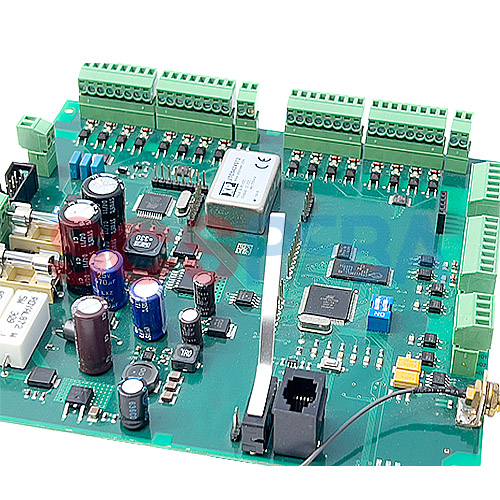

Printed Circuit Board Assemblies (PCBAs) have several strengths that can be applied to the 5G industry. In the 5G industry, where the demand for small and lightweight devices is high, for example:

PCBA can enable the development of compact and portable 5G equipment such as routers, base stations, and IoT devices.

PCB assembly manufacturing can be designed with high-quality materials and optimized trace layouts to ensure reliable signal integrity and minimize signal loss.

PCB assembly can be designed to accommodate RF and microwave components, such as antennas, filters, and amplifiers, enabling seamless integration of these components into 5G devices.

With advanced manufacturing techniques like multi-layer PCB assembly and surface mount technology (SMT), PCB assembly manufacturing enables efficient integration and improved performance in 5G devices.

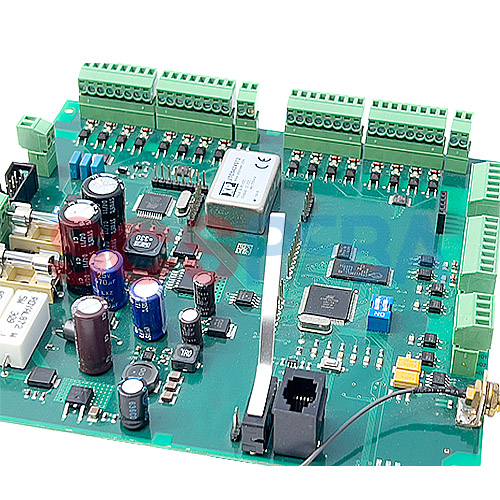

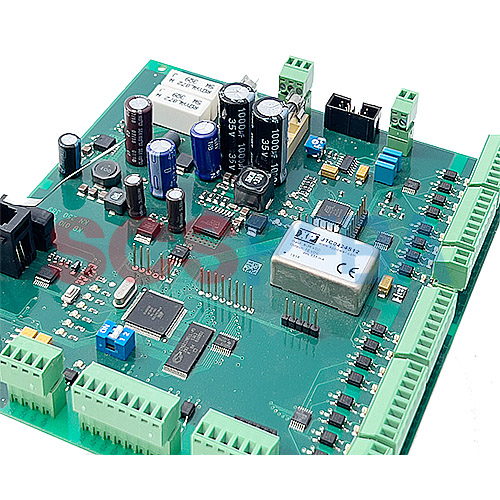

5G technology operates at higher frequencies compared to previous generations. High-frequency design considerations must be taken into account during PCB layout and fabrication processes, Issues such as signal loss, impedance matching, and electromagnetic interference (EMI) become more critical. Specialized printed circuit board design techniques, controlled impedance, and RF testing are required to address these challenges. Adequate heat dissipation mechanisms, such as heat sinks, thermal vias, and effective airflow, should be incorporated into the PCB design.

The selection of suitable printed circuit board materials becomes more important in 5G manufacturing. The chosen PCB materials should have low signal loss, low dielectric constant, and high thermal conductivity. Collaboration between PCB design engineers and PCB assembly manufacturing teams is crucial to address potential manufacturing challenges and optimize the PCB and PCBA manufacturing processes.

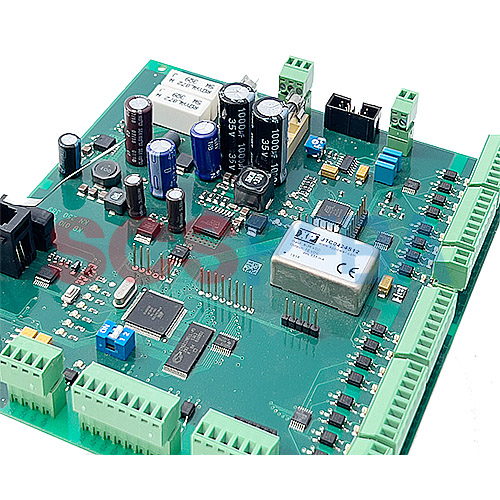

It is important to consider PCB component availability and long lead times, especially for specialized or new components used in 5G devices. PCBAs must undergo thorough testing for functionality, signal integrity, and adherence to specifications. Specialized testing equipment capable of handling high frequencies and fast data rates should be employed to verify the performance of 5G in PCB assembly manufacturing.

Choosing the right PCB assembly manufacturer is crucial to avoid problems in the production of 5G products. Here are some factors to consider when selecting a PCBA manufacturer:

Look for a manufacturer with a proven track record and extensive experience in PCB fabrication and PCBA manufacturing, especially in the field of high-frequency and high-speed applications.

Evaluate the PCBA manufacturer's capabilities in terms of technology and equipment. Check if they have state-of-the-art facilities, advanced machinery, and the ability to handle the specific requirements of 5G PCBAs, such as high-frequency testing, surface mount technology (SMT), and controlled impedance capabilities.

Make sure that the PCB assembly manufacturer follows strict quality control processes and holds relevant certifications, such as ISO 9001 or IPC standards.

Consider the PCBA manufacturer's supply chain management capabilities. They should have established relationships with reliable component suppliers and the ability to source components effectively, especially for specialized or scarce components used in 5G devices.

Assess the PCB and PCB assembly manufacturer's ability to provide design support and collaborate with your engineering team. Effective communication and collaboration during the PCB assembly design stage can help identify and address potential PCB assembly manufacturing challenges, optimize the PCB design for manufacturability, and ensure 5G products' smooth production.

SCSPCBA offer PCB design support services to assist 5G customers in optimizing their PCB designs for manufacturability and performance. We collaborate closely with customers' engineering teams to understand their specific requirements in PCB fabrication, PCB layout, PCB prototype or PCB assembly manufacturing, etc. Our professional PCB assembly service team provides design feedback and suggests improvements.

PCB prototyping and rapid iteration are critical to success in the 5G industry.

● Reliable Partner Choice

SCSPCBA experienced PCB assembly manufacturers and design teams make sure we have expertise in high-speed signal transmission and 5G applications.

● Rapid PCB Prototyping

SCSPCBA can provide rapid prototyping services. This will shorten the cycle time from PCB design to actual prototype and help to quickly verify the design. We also use a modular design approach, proven modules can be reused during the PCB design process, saving time and effort.

● Parallel Development

SCSPCBA support running the PCB design and PCB assembly manufacturing processes in parallel, rather than waiting for the PCB design to be completed before PCBA manufacturing. This saves time and speeds up the overall 5G project.

● Teamwork

SCSPCBA builds an efficient PCB team to ensure effective collaboration between designers, engineers and manufacturers. This will help reduce misunderstandings and communication issues and improve PCB assembly manufacturing efficiency.

SCSPCBA establishes a long-term cooperative relationship with trusted PCB component suppliers, maintains regular communication with suppliers, and shares project plans and forecasts so that they can prepare and adjust production plans in advance to ensure timely delivery and priority supply of 5G product PCB components. At the same time, we are introducing alternative suppliers in the PCB component supply chain, which helps to spread risks and provide alternative options when the original component supplier encounters problems.

We have established a smart cloud component warehouse to monitor and manage inventory levels to ensure timely replenishment of inventory to meet customer needs. Assist customers to find suitable PCB assembly replacement parts, reduce supply chain risk, and effectively solve the problem of parts shortage. At the same time, the intelligent cloud component warehouse can ensure the transparency of the PCB supply chain, and keep abreast of the delivery status of components and the production capacity of suppliers, so that they can quickly make adjustments when demand fluctuates.

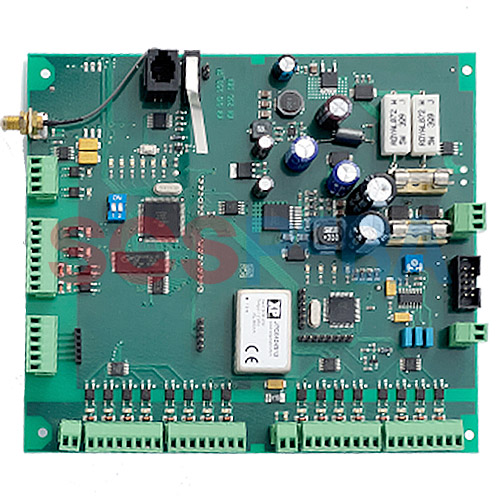

SCSPCBA offers PCB and PCBA customization options to meet the unique requirements of 5G customers. Flexibility in PCBA manufacturing capabilities, such as accommodating different PCB assembly sizes, specialized materials, and specific assembly techniques, allows customers to tailor 5G products to their exact needs.

Implement robust quality control processes and comprehensive testing methodologies to ensure the reliability and performance of PCBAs.

Both our PCB plants and PCBA factory are qualified with ISO9001:2015, ISO14001:2015, IATF16949:2016 and ISO13485:2016, and they are also in compliance with IPC-A-600 & IPC-A-610 quality certification. We also establish a strict manufacturing process and train operators to ensure standardization and compliance of operations. Implement process control and monitoring to ensure stability and consistency at each manufacturing step.

SCSPCBA uses automated testing equipment for automated testing of patch and soldering quality, including AOI (Automated Optical Inspection) and AXI (Automated X-ray Inspection).

Perform functional testing to ensure the PCBA works as expected.

We establish a quick feedback channel with our customers to keep abreast of their needs and opinions. This allows potential problems to be caught and resolved at an early stage.

We provide responsive technical support, solve customer inquiries, solve problems and provide guidance throughout the PCB design to PCB assembly manufacturing life cycle, after-sales services such as warranty support, repair and replacement, to ensure that customers still have us as a reliable and reliable partner after product delivery.