HOME /Products /PCBA Services /PCB Assembly

☑ Fast delivery for small and medium batch PCB assembly manufacturers

☑ Small and medium batch orders, more reasonable price and cost advantages

☑ Stability and reliability of each PCBA product to meet customers' flexible needs

☑ Have a flexible production environment and technical team

☑ An ideal solution for small and medium-volume PCB assembly manufacturers

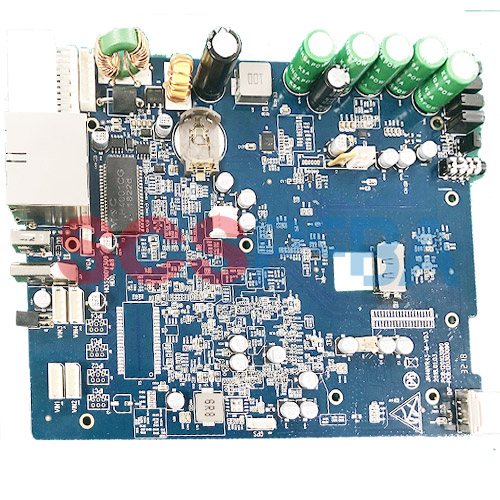

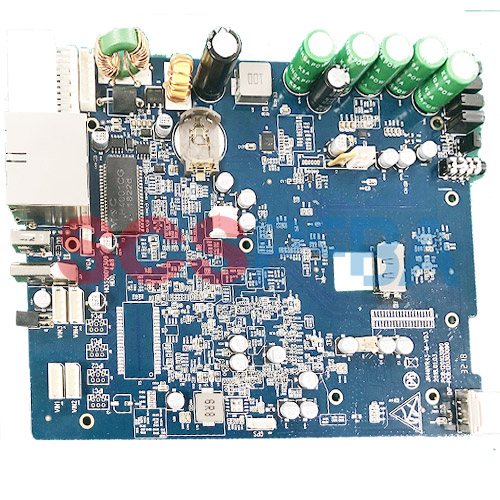

Small and medium batch PCB assembly refers to the placement and welding of components for PCBs (printed circuit boards) with small orders in the manufacturing process of electronic products. PCB is an important part of electronic products, on which various electronic components, such as integrated circuits, resistors, capacitors, inductors, etc., are used to realize circuit functions.

SCSPCBA provides small and medium batch PCB assembly, which is carried out by our professional PCB assembly factory.

Small and medium batch PCB assembly is suitable for electronic product sample production, small-scale production, fast delivery and other needs, and is an important link in the development and production process of electronic products.

Before starting the assembly, SCSPCBA will first confirm with the customer and carry out PCB design according to the needs to ensure that the PCB layout is reasonable, meets the functional requirements of the circuit, and is suitable for subsequent component mounting and welding. Optimizing layout can improve signal transmission efficiency and thermal performance.

According to the bill of components (BOM) of PCB design, select the appropriate component supplier and purchase components. SCSPCBA has an intelligent component warehouse, no need for customers to find other component suppliers, we provide customers with the required components, to achieve timely supply, to avoid delays in PCB assembly progress.

The stencil is a key tool for positioning and pasting SMT components and makes a steel mesh according to the PCB design file.

SCSPCBA uses automated placement equipment to quickly paste surface mount components on the PCB.

Some components on the PCB cannot be mounted by automatic placement equipment, and need to be placed through manual insertion.

Through the wave soldering or reflow soldering process, weld the components to the PCB, and check the welding quality.

● SCSPCBA is a one-stop PCBA manufacturing service provider with rich experience

● SCSPCBA also provides assistance in PCB design, PCB manufacturing and assembly testing

● It is based on IPC standards for small and medium-batch PCB assembly

● The workshop is also equipped with online SPi and online AOI testing equipment

In the process of PCB production, automatic equipment and an online DFM inspection system are introduced to catch potential problems in time. For example, automated optical inspection (AOI) systems are employed to check component mounting positions and deviations, and soldering quality to standards.

● Offline Detection

Conduct offline sampling detection to verify the accuracy of online detection results. Laboratory testing is carried out by taking samples to confirm whether the product quality is as expected.

● X-ray Inspection

For components that are difficult to inspect directly such as BGA (Ball Grid Array), X-ray inspection technology is used to ensure the quality and integrity of solder joints.

● Functional Testing

After the assembly is completed, conduct functional testing to verify whether the performance of the PCB meets the design requirements.

● Introduce A Traceability Mechanism

SCSPCBA establishes a traceability mechanism throughout the printed circuit board production process to record the operating data and key parameters of each link. Once a problem occurs, the point of failure can be quickly located so that measures can be taken quickly.

● Troubleshooting Team

SCSPCBA has set up a special troubleshooting team, which is composed of experienced technicians. For complex PCB assembly faults, conduct in-depth cause analysis and formulate corresponding repair plans.

● Regular Maintenance

Regularly maintain and maintain PCB fabrication and PCBA manufacture production equipment to ensure that they are always in the best condition.

● Defective Product Handling

When there are defective PCBs or PCBAs, SCSPCBA will promptly isolate and investigate the cause of the defective PCB assembly, conduct a detailed analysis and take corrective measures to avoid similar problems from happening again.

● Reasonable Selection of Components and Equipment

In the component selection stage, SCSPCBA prioritizes cost-effectiveness. Look for components with reasonable performance and quality, establish a good cooperative relationship with PCB component suppliers, and strive for price concessions and delivery flexibility.

● Reduce Material Waste and Costs

Reduce material waste with accurate component requirements planning and intelligent inventory management. Avoid excessive component procurement and inventory backlog, so as not to cause resource waste and capital occupation.

At the same time, SCSPCBA has set up a special procurement team to negotiate with component suppliers, explore procurement batch discounts, and ensure timely supply from suppliers.

● Optimize Manual Scheduling

SCSPCBA has designed an efficient staffing plan to avoid waste caused by over or under-staffing. Reasonably arrange the working hours of employees to ensure the stable operation of the PCB assembly line.

Regularly train employees to improve PCB assembly skill level and work efficiency. SCSPCBA believes that skilled employees can deal with problems more quickly, reducing unnecessary downtime and rework.

● Improve Production Efficiency

Optimize the PCB assembly production process, and reduce non-value-added links and waiting time. Introduce automated equipment, such as placement machines, reflow ovens, etc., to improve assembly speed and accuracy.

SCSPCBA sets up PCB assembly production performance evaluation indicators to monitor production efficiency and make improvements. Encourage employees to put forward improvement suggestions to promote continuous improvement of production efficiency.

SCSPCBA will further develop in the direction of automation and intelligence for small and medium-batch PCB assembly in the future. The application of automation equipment will greatly improve the efficiency and accuracy of PCB assembly production and reduce labor costs. Smart manufacturing technology will make the production process more intelligent and traceable, providing more comprehensive data support for quality control.

SCSPCBA will also pay more attention to environmental protection and green manufacturing. The use of low-energy consumption equipment, environmentally friendly materials and recycling technologies reduces the impact on the environment and is in line with the trend of sustainable development.

With the popularization of 5G technology and the increasing number of Internet of Things applications, small and medium-batch PCB assembly will usher in new market opportunities. The small and medium batch PCB assembly provided by SCSPCBA can meet the needs of 5G communication modules, IoT devices and other PCB design, PCB manufacturing, etc.

The application of consumer electronic products is becoming more and more extensive. SCSPCBA aims to help enthusiasts and enterprises who want to enter the field of consumer electronics to provide PCBA assembly of consumer electronics.

The vigorous development of the new energy vehicle and electric automotive market will stimulate the demand for small and medium-volume PCB assembly. The assembly of electric vehicle electronic control systems, charging piles and other products has become a key PCB assembly project of SCSPCBA.

As the medical industry continues to grow, the demand for medical electronics will also increase. Small and medium batch PCB assembly will play an important role in medical equipment, health monitoring equipment, etc.