☑ High quality More Than 10 years.

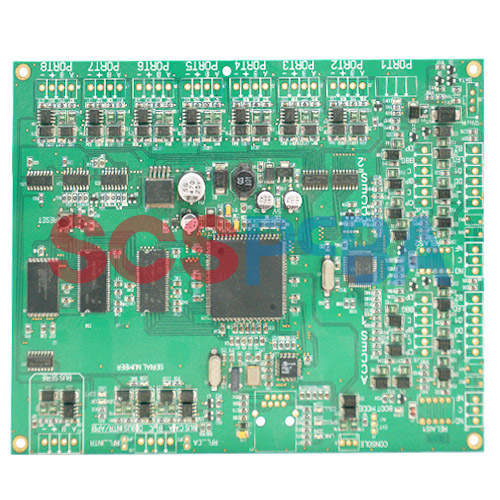

☑ Military-grade PCB Specifications for Design

☑ Requirements on Military Electronics PCB Assembly

☑ Military & Defense PCB, Military Component Supplier

☑ Offer TurnKey Manufacturing with One-Stop PCBAService

As various countries accelerate the development of military intelligence in order to strengthen their national defense capabilities, military equipment must be more intelligent and cutting-edge to further improve core combat effectiveness.

The military PCBA industry is becoming increasingly strict. There are strict requirements in terms of reliability, stability, and safety, and correspondingly higher requirements for PCB manufacturing, PCB process, PCB production control, etc. In addition, circuit board companies need to pass multiple strict quality system inspections and certifications.

The main purpose of the military PCBA standard is to ensure the reliability, stability and safety of military electronic equipment, and its content covers PCB design, PCB assembly manufacturing, PCBA functional testing and quality control.

It is required to use materials with high reliability and high-temperature tolerance, such as high-temperature FR-4 printed circuit board materials, high-reliability printed circuit board electronic components, etc.

Including the PCB fabrication process, component welding process, etc. Military PCBA requires a stable and reliable manufacturing process, and advanced manufacturing equipment and technology must be used to ensure the quality of PCB assembly.

Including functional testing, reliability testing, environmental adaptability testing, etc. Military PCBA requires strict testing to verify the function and performance of the circuit to ensure that it can work normally in harsh environments.

Including process control, inspection and quality management. The military industry PCBA requires the establishment of a sound quality control system to strictly control the entire process from printed circuit board raw material procurement to final PCBA delivery to ensure product quality.

In recent years, the military's demand for military products has gradually shown a trend towards customization, multi-variety, and small batches; Comprehensive requirements were put forward for service characteristics and economy, and the specific goals of "easy to use, effective, durable, practical, and beautiful" were formulated accordingly. This poses a big challenge to the traditional quality assurance system of the military industry. It is also a test of the quality and customization capabilities of military PCB assembly manufacturing.

SCSPCBA will meet the quality requirements and customized services of military PCBA in the following aspects:

Our two PCB plants are located in Jiangsu province and Jiangxi province, and our State-of-the-Art PCB Assembly line is located in Shenzhen, China. uses an advanced digital management system, complies with ISO9001:2015, ISTF16949, ISO14001 and other quality system certification and environmental requirements, and fully meets the different requirements of PCBA for various military products on PCB materials and processes.

SCSPCBA has more than 10 years of cooperation with professional and excellent supplier channels, continuous and stable cooperative relations, traceable components, guaranteed quality, a modern PCB component management system, and better control of procurement costs.

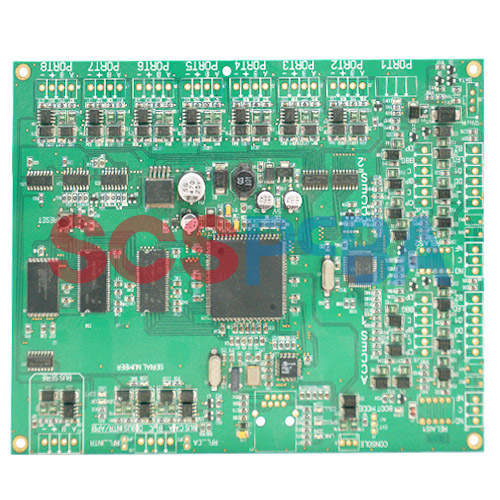

SCSPCBA has 4 SMT production lines, 2 plug-in lines, 2 wave soldering lines, 2 manual assembly and functional testing lines, and 1 packaging line.

● AOI Testing Equipment

AOI inspection equipment automatically scans PCBA products through high-definition CCD cameras, collects images, compares test points with qualified parameters in the database, and checks out solder joint defects on the target PCBA through image processing, and displays or automatically marks defects. Improve process parameters for maintenance personnel maintenance and SMT craftsmen.

● X-ray Inspection Equipment

For some parts that cannot be detected by visual inspection, such as BCA solder joints, inside of PCB through holes and other internal defects, and the positioning of defective solder joints of high-density packaged BGA or CSP devices, X-ray perspective systems have to be used for inspection. The X-ray fluoroscopy system uses the different principles of different material thicknesses or different material densities for X-ray moisture absorption or transmittance to the image.

SCSPCBA is equipped with an advanced and complete digital management system and is committed to building an industrial 4.0 smart factory. It has perfect industry 4.0 solutions, PCBA processing services, SMT patch processing services, PCBA reliability function testing services, OEM electronic processing services, ODM OEM and material services.

With the further advancement of global national defense modernization, weapons and information equipment have entered a critical period of technological iteration, driving the rapid growth of the military PCBA market.

Military System PCBA Application and Coverage

A radar detector is an electronic device that uses electromagnetic waves to detect targets, emits electromagnetic waves to irradiate the target and receives its echoes, thereby obtaining information such as the distance, distance change rate, azimuth, height, etc. from the target to the electromagnetic wave emission point.

Measuring equipment not only refers to the measuring instrument itself but also extends to auxiliary equipment, because related auxiliary equipment will directly affect the accuracy and reliability of measurement. This mainly refers to equipment that cannot provide a quantitative value and cannot be measured without it, and experimental hardware or software used as a detection method, such as tools, fixtures, positioners, molds, etc. It can be seen that, as an auxiliary device for measurement, it is very important to ensure the uniformity and accuracy of measurement.

● Environmental Monitoring Section

If an unexpected situation occurs outside, communication may be affected. Therefore, the communication command vehicle is equipped with internal and external environment monitoring devices. Including ambient temperature, humidity, wind speed, and harmful gases, to ensure that the communication command vehicle can maintain a comfortable and safe working environment. Built-in on-board air conditioning also helps ensure that all mission-critical communications systems operate at safe temperatures.

● Emergency power generation sector

Most operational communication command vehicles require some form of active on-site power. Most can be equipped with on-board diesel as a generator (optional), with an electric power of 8 kW to 30 kW.

They are installed in ventilated, insulated rooms, mostly near the rear of the vehicle, in order to reduce interior noise and improve interior comfort.

If there is no communication mobile phone (including satellite phone), the mobile communication command vehicle will be restricted in use. You can find communication command vehicles with various communication functions according to your budget and purpose.