☑ With PCBA Manufacturing achieve Compact and Space-Efficient Designs

☑ PCB Assembly leads to prolonged battery life and enhanced user experience

☑ PCBA manufacturers provide support for innovation and collaboration

☑ Supports PCB Assembly Prototyping in the Consumer Electronics

☑ Trusted by 1000+ customers

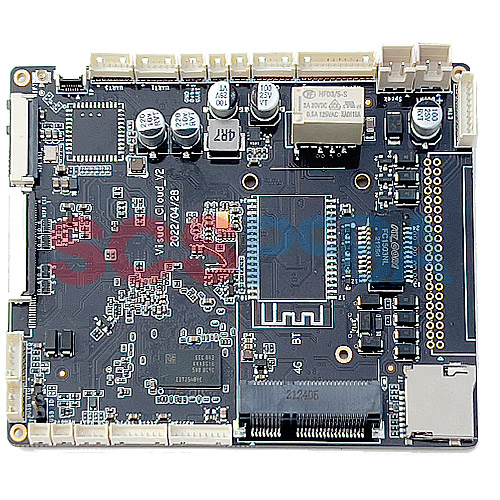

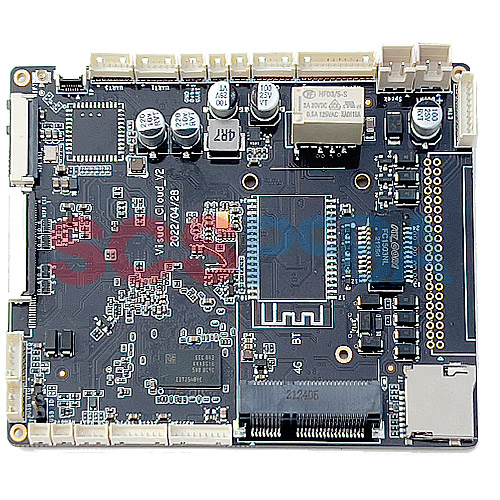

The basic characteristics of consumer electronic products are their miniaturization and diversification. As a result of these two major trends, assembly techniques for consumer electronics PCB Boards are becoming increasingly complex, thereby attracting greater attention in the PCB assembly manufacturing process. With the consumer electronics development of diversification and the continuous shortening of the life cycle, printed circuit board assembly manufacturing requires short investment time, fast turnaround, process manufacturing, and rapid production.

Consumer electronics PCBA products have always existed in our daily lives. Considering the amount of time we spend on our phones, TVs, and computers, the impact and usefulness of consumer electronics is remarkable. What ties all these products together is their reliance on the use of PCB assembly in the manufacturing process. Large-capacity printed circuit boards (low unit cost) Since the price of the electronic products used is relatively low, the additional benefit is that the use of printed circuit boards to manufacture electronic products will be cheaper and the product will be highly uniform.

According to the development trend of modern electronic products, it is an obvious trend that the size and volume of electronic products are getting smaller and smaller. People are always looking for ways to save more space. Electronics require less space because of the higher density of circuits and connections on boards. Therefore, more layers and high-density printed circuit boards are adapted for consumer electronics applications.

In the consumer electronics market, there are many homogeneous products. This is because the proliferation of technology and saturation of the market has resulted in many companies producing products with similar functions and performance. Price usually becomes an important factor in attracting consumers, because many consumers have relatively simple requirements for products, and as long as the functions meet their needs and the price is reasonable, their willingness to purchase can be satisfied.

In such a market environment, PCB (Printed Circuit Board, printed circuit board) assembly and production have become a very important link. Since most consumer electronic products use similar electronic components and designs, the cost of the PCB assembly process is relatively stable. Therefore, fierce competition has been launched among enterprises to grab more orders and market share.

Different from low-end consumer electronics products that pursue the ultimate cost performance, high-end consumer electronics products have strict requirements on PCB materials and fabrication.

· Complexity and Density

High-end consumer electronics typically require more complex and denser PCBA Manufacturing. This means that more components need to be placed on the PCB assembly, and the spacing between these components is smaller. Therefore, the production process requires a higher level of precision and skill to ensure that components are installed and connected correctly while avoiding short circuits or other manufacturing defects.

· High-performance Requirements

High-end consumer electronics products typically have higher performance requirements such as faster processing speeds, higher energy efficiency and more reliable functions. This requires that the PCBA design and manufacture must have higher quality standards to ensure stable and reliable product performance. For example, HDI boards have higher and higher requirements for inner layer wiring and graphic size control. There are many layers, and the thin core board is easy to wrinkle, which makes it more difficult to control the alignment accuracy between the inner layers, and also increases the production cost.

· Variety and Customization

The demand for product diversity and customization in the high-end consumer electronics market continues to increase. Consumers have higher expectations for personalized products and functions, which means that PCBA manufacturers must have greater flexibility and be able to adapt to various product designs and requirements.

· Packaging Technology

Some high-end consumer electronics products adopt new packaging technologies, such as BGA (Ball Grid Array), which require a higher technical level and more advanced equipment in the PCBA manufacturing and soldering process.

Due to the short life cycle of consumer electronics products, rapid demand updates, and the ever-changing consumption preferences of consumers, the rapid replacement of consumer electronics products has brought great challenges to PCBA manufacturers.

PCBA for consumer electronics often involves more suppliers and partners. In a globalized supply chain, ensuring the timely supply of components, quality control, and cost efficiency has become more complex and critical.

The consumer electronics market is highly competitive, and product updates and iterations are fast. To meet consumer needs, printed circuit board manufacturers must continue to conduct R&D and innovation and adopt new materials, processes, and technologies to improve the performance and reliability of PCBA.

materials Due to geopolitical regulation, supply chain security has become more and more challenging, how to obtain stable supply at competitive prices has become a major task for the supply chain team.

The consumer electronics market is changing rapidly and requires a flexible PCBA manufacturer that can customize production according to your needs. This can better meet the different needs of consumers

Experience consumer electronics PCB products must meet people's daily work and life requirements. Boards used in high-end consumer electronics often require small form factors, resulting in higher density requirements. Having an official certificate, ISO, UL or RoHS helps to prove the capability of a PCB manufacturer and regulate the whole manufacturing process.

First of all, we are a one-stop PCBA manufacturer with rich experience and expertise. We have a certain history and success stories in the field of consumer electronics manufacturing. Secondly, we have advanced production equipment and technical capabilities, which can meet high-density, multi-layer PCB and special packaging requirements. In addition, there are perfect quality control measures and testing methods to ensure the quality and reliability of consumer electronics PCB assembly manufacturing.

SCSPCBA has quality certification PCB and PCBA certification, and has a complete quality management system, such as ISO 9001 certification, to ensure customer quality and product certification requirements. It can ensure that consumer electronics PCB assembly manufacturing meets international quality standards.

The customer only needs to be responsible for payment and receipt, and the cost calculation is convenient and clear. We are responsible for the unified integration of components and other material and component resources, and the professional quality inspection department inspects incoming materials to reduce customer self-purchase, loss, time and inventory costs. Professional material management systems and warehousing, component storage and extraction are convenient.

Today's technological products iterate very fast, and time determines the living space. We have a complete department system to reduce the circulation links in product production, improve quality traceability, and ensure quality consistency. PCB manufacturing, intelligent component warehouse, printed circuit board processing, testing, assembly, and after-sales maintenance are all completed here. , one-stop service, avoiding the risk of delivery delays due to insufficient capacity of PCBA manufacturers, and reducing customer concerns.

We are a PCBA manufacturer who can establish a long-term cooperative relationship and can provide customers with guaranteed stable consumer electronics product quality and continuous after-sales technical support.

Consumer PCB assembly products mainly have the following scenarios

● Entertainment Electronics

· Wearables

· Wearables

· Smartphones

· Smartwatches

· Routers

· TVs

· Set-top Boxes

· Laptops

· Desktops

· Printers

· Shredders

·Smart Home

·Refrigerators

·Washing Machines

·Smart Kitchen Utensils

·Baby Appliances

● Other

· Devices Brought by 3D Sensing Technology

· Bluetooth Headset Power Supply

· Charger

· LED Lights