☑ Automotive PCB Applications and Types

☑ Printed Circuit Boards for Vehicle Electronic Industry

☑ PCB Prototype and Fabrication Manufacturer

☑ One-stop solution for PCB assembly

☑ Focused and responsive design and manufacturer

Automotive electronic products can be divided into two categories. The first category is automotive electronic control devices, and the second category is vehicle electronic devices.

Automotive PCBA will continue to actively promote the development of automotive intelligence. With the continuous maturity of technologies such as artificial intelligence, the Internet of Things and automatic driving, automotive PCBA will play an increasingly important role in the realization of automatic driving, intelligent transportation, and the Internet of Vehicles. At the same time, the continuous emergence of emerging technologies will also provide more development opportunities for automotive PCBA.

SCSPCBA is taking action to take automotive electronics an important development area for our future PCBA manufacturing. In short, as an important support for the intelligent upgrade of automobiles, the role and significance of automotive PCBA are self-evident. With the continuous advancement of technology and the continuous expansion of applications, automotive PCBA will provide more intelligent functions for cars, and realize people's higher expectations for driving safety and driving experience. In future development, we have reason to believe that automotive PCBA will continue to maintain an important position in the field of intelligent vehicles and contribute more technological strength to the development of automobiles.

SCSPCBA has been supplying high-quality, competitively priced PCB assemblies (PCBA) for over a decade. One of the main markets we serve is the automotive industry.

SCSPCBA's advantages in producing PCBA of automotive electronic products.

SCSPCBA provides one-stop full turnkey service from PCB manufacturing, and component procurement to PCBA manufacturing, helping our customers save time and effort.

Secondly, among the PCBA product types, automotive electronic products occupy an important position. With the promotion of automotive electronics by automotive intelligence and the vigorous development of new energy vehicles, the demand for automotive PCBA has entered a new round of growth, and the industry has arrived.

Under this opportunity, relying on strong technical research and development capabilities, customized process development advantages, good product quality performance and fast order response capabilities, SCSPCBA has gained a firm foothold in the automotive PCB market. Especially in the field of new energy vehicle PCB applications, the company's products widely cover battery management systems (BMS), motor controllers, on-board chargers, charging piles, automotive electronic control devices, vehicle electronic devices, electric vehicles electronics, electric motorcycle electronics and other core components and supporting facilities, and have strong competition in the field of new energy vehicle BMS Advantage. A group of well-known customers at home and abroad.

The factory strictly follows ISO9001:2015, IATF16949 and other standards for production and management.

Automobile-related PCBA is a product that may involve life safety. During the manufacturing process, all links must be strictly controlled to avoid errors and ensure a 100% pass rate.

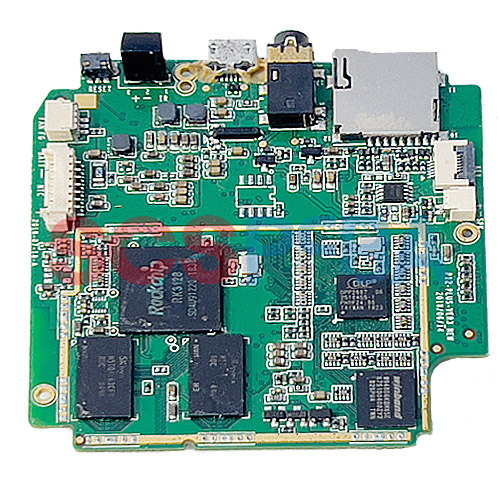

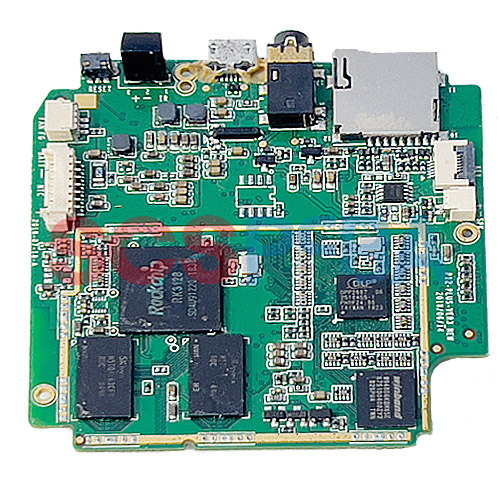

A modern car is a complex product, with diverse accessories and functions requiring powerful electronics and systems. High-quality manufacturing of complex printed circuit board designs is key to vehicle operating efficiency and safety. As a key component of almost all electronic devices and systems, PCBAs used in the automotive industry must be carefully designed and manufactured to ensure they meet performance targets and relevant industry standards.

As an automotive PCBA factory, SCSPCBA's comprehensive strength (PCB design, PCB fabrication, DFM checking, components procurement, PCB assembly, BGA assembly, firmware programming, functional testing and box-build) all meet the requirements of automotive product customers.

Due to the special working environment, safety and high current requirements of automobiles, the requirements for the reliability and environmental adaptability of PCB circuit boards are very strict. Zero defect rate is the basic requirement of international manufacturers for suppliers, and it also determines whether they can enter the field of automotive PCBs.

SCSPCBA has a PCB plant and a PCBA factory, uses an advanced digital management system, complies with ISO9001:2015, ISTF16949, ISO14001 and other quality system and environmental requirements, and fully meets the different requirements of different automotive Electronic PCB and Vehicle Electronic Devices PCBA for materials and processes.

The dashboard communication system provides the driver with information about the condition or performance of the vehicle. They typically use flex, multilayer and HDI PCBs.

The Vehicle navigation system provides the driver with location information and directions. They usually use embedded PCBs.

The vehicle power controller balances the energy flow within the electric vehicle. They usually use embedded PCBs.

Self-driving cars drive with little to no driver involvement. They usually use HDI PCB.

The E security system prevents theft of the vehicle by providing automatic locking or remote locking functions and sounds an alarm when potential theft is detected. They typically use flex, multilayer and HDI PCBs.

The HVAC system allows the driver to adjust the temperature and airflow in the car. They usually use single-layer or double-layer PCBs.

SCSPCBA has more than 10 years of cooperation with professional and excellent supplier channels, continuous and stable cooperative relations, traceable components, guaranteed quality, modern component management system, and better control of procurement costs.

● SCSPCBA Manufacturing Capacity

Printed Circuit Board manufacturing and assembly capabilities: 4 SMT production lines, 2 plug-in lines, 2 wave soldering lines, 2 manual assembly and functional testing lines, and 1 packaging line.

● SCSPCBA Services

SCSPCBA is equipped with an advanced and complete digital management system and is committed to building an industrial 4.0 smart factory. It has perfect industry 4.0 solutions, PCBA processing services, SMT patch processing services, PCBA reliability function testing services, OEM electronic processing services, ODM OEM and material services.

With the continuous advancement of science and technology and people's expectations for intelligent vehicles, automotive electronic PCBA, as an important part of automotive electronics technology, is gradually attracting widespread attention. As an important carrier of automotive electronic components, PCBA plays a key role in the intelligent upgrading of automobiles.

The role of automotive electronic PCBA is not only to integrate and connect various electronic components but more importantly, to provide a stable power supply, efficient signal transmission and reliable data processing capabilities for the intelligent system of the car. Through PCBA, various sensors, control units, embedded systems, etc. can be effectively integrated and interact and transmit data in real-time with other systems of the vehicle. These intelligent functions not only improve the driving safety and comfort of the car but also provide more intelligent driving assistance and entertainment functions.

● Automotive Safety System

PCBA can undertake functions such as airbag control, braking system and driving assistance system;

● Car Entertainment System

PCBA is responsible for the control of audio, video and navigation functions;

● Vehicle Communication System

PCBA plays a key role in data transmission and connection.

It can be said that automotive electronics PCB assembly manufacturing is one of the core technologies for realizing automotive intelligence.